Discover the secret to faster, error-free inspections by understanding how inline SPI machines save time in your PCB assembly line.

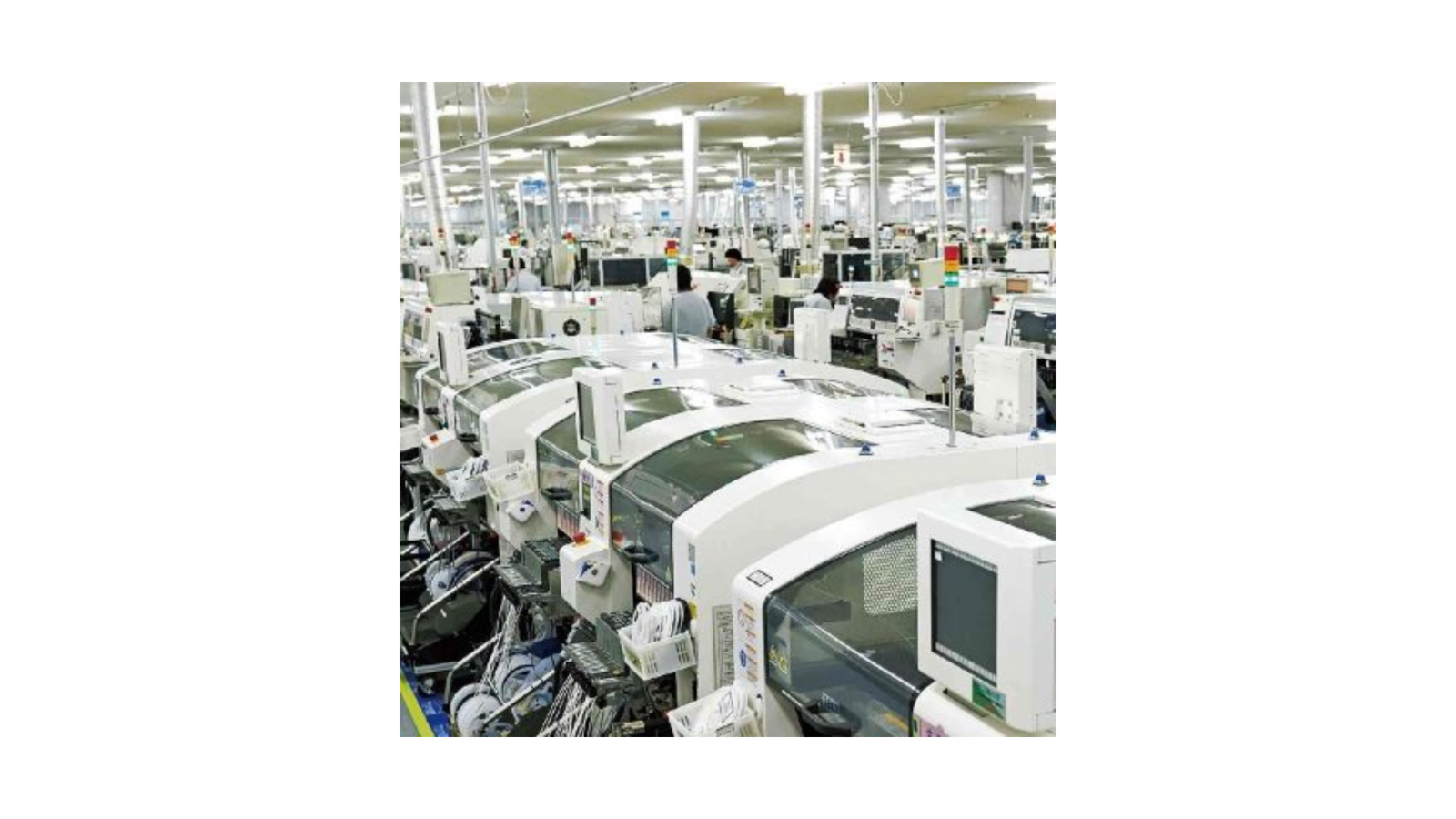

Let’s streamline your SMT production line!

One of the most important steps in a PCB assembly line is the solder paste inspection. This process directly determines the production line quality and speed.

An inline solder paste inspection machine ensures that only perfect boards move forward to pick-and-place and reflow soldering stages, as fast as possible. But how?

By integrating the SPI machine directly into the SMT line, manufacturers not only save valuable time but also improve consistency and reduce scrap. Let’s understand this better!

How Inline SPI Machines Save Time: Enhancing PCB Quality

What are Solder Paste Inspection Machines?

Solder Paste Inspection (SPI) machines are designed to check solder paste deposits on printed circuit boards with high precision. SPI machines provide accurate, repeatable results in a fraction of the time.

This precision ensures that downstream processes, like pick-and-place and reflow soldering, proceed smoothly, reducing rework and scrap rates.

Understanding the Importance of Speed in PCB Production

In electronics manufacturing, every step in the assembly process impacts the overall production timeline. Delays in inspection can stall pick-and-place machines and slow reflow lines.

By integrating an inline SPI machine, manufacturers significantly reduce inspection time per board, ensuring a seamless flow across the production line. For large-scale projects, this translates to hours saved daily, time that can be redirected to meeting higher demand or handling more complex boards.

How Inline SPI Machines Enhance PCB Assembly Speed

1. High-Speed Scanning

Modern inline SPI machines scan entire PCBs within seconds, detecting areas of insufficient, excessive, or misaligned solder paste. Rapid scanning allows boards to move quickly from the printing stage to pick-and-place systems, reducing idle time and keeping the production line flowing seamlessly.

2. Immediate Feedback and Adjustments

Inline SPI machines provide real-time feedback to operators. Parameters can be adjusted instantly, minimizing delays caused by recurring defects and ensuring each board meets quality standards the first time. This proactive approach keeps production moving without interruptions.

3. Early Detection of Defects

By identifying issues such as bridging, misalignment, or inconsistent solder volume at the earliest stage, inline SPI machines prevent time-consuming rework. Boards with potential errors are flagged before reaching critical stages, saving hours that would otherwise be lost addressing quality issues later.

4. Supports the Entire SMT Lines

Inline SPI machines integrate directly with other SMT equipment, including pick-and-place machines and reflow ovens. This synchronization allows for a continuous, optimized workflow, eliminating unnecessary stops and starts, and reducing overall production cycle time.

5. Optimized Throughput for Large-Scale Production

For high-volume PCB assembly, every board counts. Inline SPI systems maintain consistent speed across complex or multilayer boards, ensuring production quotas are met without sacrificing quality. Faster inspection means more boards completed per hour, significantly improving throughput.

Practical Advice for Choosing the Right SPI Machine

When investing in an SPI system, consider the following:

● Accuracy Requirements: Match the machine’s inspection capabilities with your PCB complexity.

● Throughput Needs: Ensure the SPI machine can keep up with your production volume.

● Integration Flexibility: Look for systems compatible with existing SMT machines.

● Service & Support: Prioritize suppliers who offer installation, training, and maintenance support.

Conclusion

SPI machines are an indispensable part of modern PCB assembly lines, offering a combination of speed, efficiency, accuracy, and reliability. The integration of these machines with other SMT systems ensures a smooth, uninterrupted workflow, improving overall efficiency and output.

Streamline Your PCB Line with Premium SMT Machines

Transform your PCB assembly process with our state-of-the-art SPI machines and expert SMT line support. HJE Tech India PVT. LTD. is the one-stop SMT and THT solution.

Efficient SMT operations await you. Get in touch today!

Disclaimer: The information provided in this content is for educational purposes only and is written by a professional writer. Consult us to know more about SMT machines.

Write a comment ...