For PCB designers and manufacturers, knowing the difference between SMT and through-hole technology matters a lot. It reveals how design and assembly optimise placement, reduce costs, and improve performance.

Surface Mount Technology (SMT) and Through-Hole Technology are two distinct ways of assembling electronic components onto printed circuit boards (PCBs). Once you understand the distinction between the two, you will make the right decision for the efficiency and quality of your production line.

While Through-Hole assembly is ideal for durability and prototyping, SMT machines offer efficiency, miniaturization, and scalability. As both continue to advance, which one is the right choice for your production line? Let’s understand that together!

A Guide on the Differences Between SMT and Through-Hole Technology

What are SMT Machines?

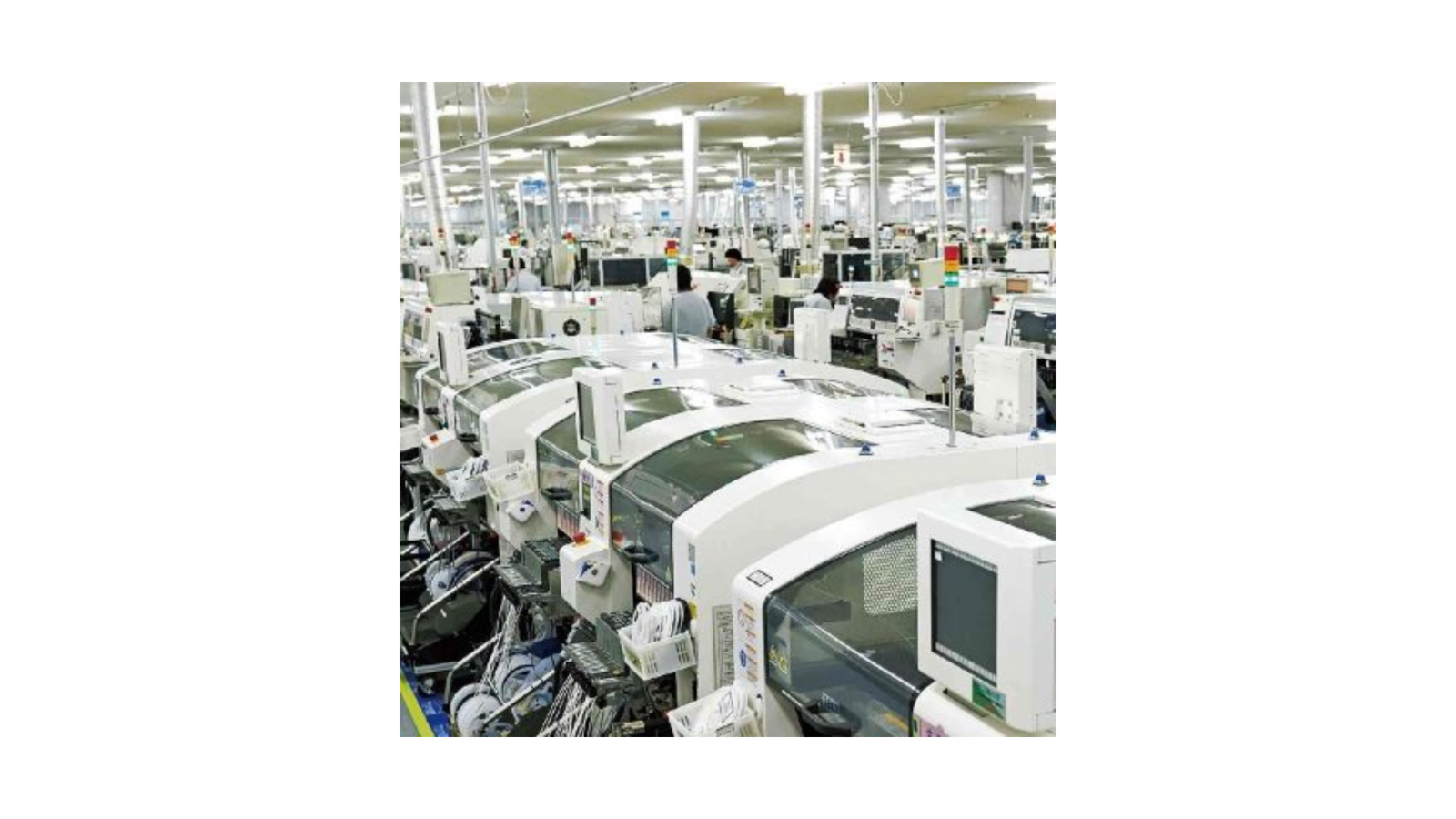

SMT is the modern standard for PCB assembly. Components, known as Surface-Mount Devices (SMDs), are placed directly on the surface of the board without drilling holes. Automated machines handle placement at high speed, and a reflow oven solders everything in place.

What are the Advantages of SMT Machines?

These are the advantages of SMT:

Compact and lightweight components.

High component density (fits more in less space).

Faster, automated assembly.

Cost-effective for mass production.

What is the Application of SMT Machines?

These are best utilised in consumer electronics, mobile devices, IoT products, automotive systems, and communication equipment.

What is the Through-Hole Technology (THT)?

THT is the older but still widely used assembly method. Here, component leads pass through drilled holes in the PCB and are soldered on the other side. While slower and more labor-intensive, it creates a stronger bond between the component and the board.

What are the Advantages of THT?

The benefits of having THT line production are:

Excellent mechanical strength.

Reliable performance in harsh environments.

Better suited for larger, high-power components.

Where is THT Best Used?

These are best applicable in aerospace, defense, industrial machinery, transformers, and prototype boards.

Differences Between SMT and Through-Hole Technology

Feature

Surface Mount Technology (SMT)

Through-Hole Technology (THT)

Mounting Method

Components placed on the surface

Leads inserted through holes

Component Size

Small, lightweight

Larger, bulkier

Assembly Speed

Automated, very fast

Manual or wave soldering is slower

Mechanical Strength

Moderate, not ideal for stress

Strong and durable

PCB Density

High — ideal for miniaturization

Lower — requires more space

Cost

Lower for high-volume production

Higher due to drilling and labor

Best Suited For

Compact devices and mass production

High-reliability and heavy-duty products

Which Technology is the Right Choice for You?

Choose SMT if your product needs to be small, lightweight, and manufactured at scale.

Choose THT if durability, strength, and reliability are top priorities.

Choose both if your design demands a mix, for example, using SMT for compact parts and THT for connectors or high-stress components.

Final Thoughts

With advancements in SMT machines, manufacturers can now achieve greater precision, consistency, and cost-efficiency in mass production. However, certain applications, such as power electronics, automotive systems, and industrial machinery, still rely on Through-Hole components for their robustness.

Remember, SMT and THT are not competitors. They’re complementary.

Your choice ultimately depends on factors like product function, size, and reliability requirements. In many cases, the most effective solution is a hybrid approach that leverages the benefits of both technologies.

Choose the best THT and SMT machines from a reliable provider. Choose HJE Tech India PVT. LTD.

Why Partner with HJE Tech?

At HJE Tech India PVT. LTD., we specialize in advanced PCB assembly solutions, offering both Surface Mount Technology and Through-Hole Technology to meet diverse project requirements.

Whether you need compact, high-volume production or durable boards for heavy-duty applications, our expert team delivers precision, quality, and reliability at every stage.

Explore our extensive inventory today!

Disclaimer: The information provided in this content is just for educational purposes and is written by a professional writer. Consult us to know more about SMT machines.

Write a comment ...