Do you know the importance of curing oven in PCB assembly? This blog is for you.

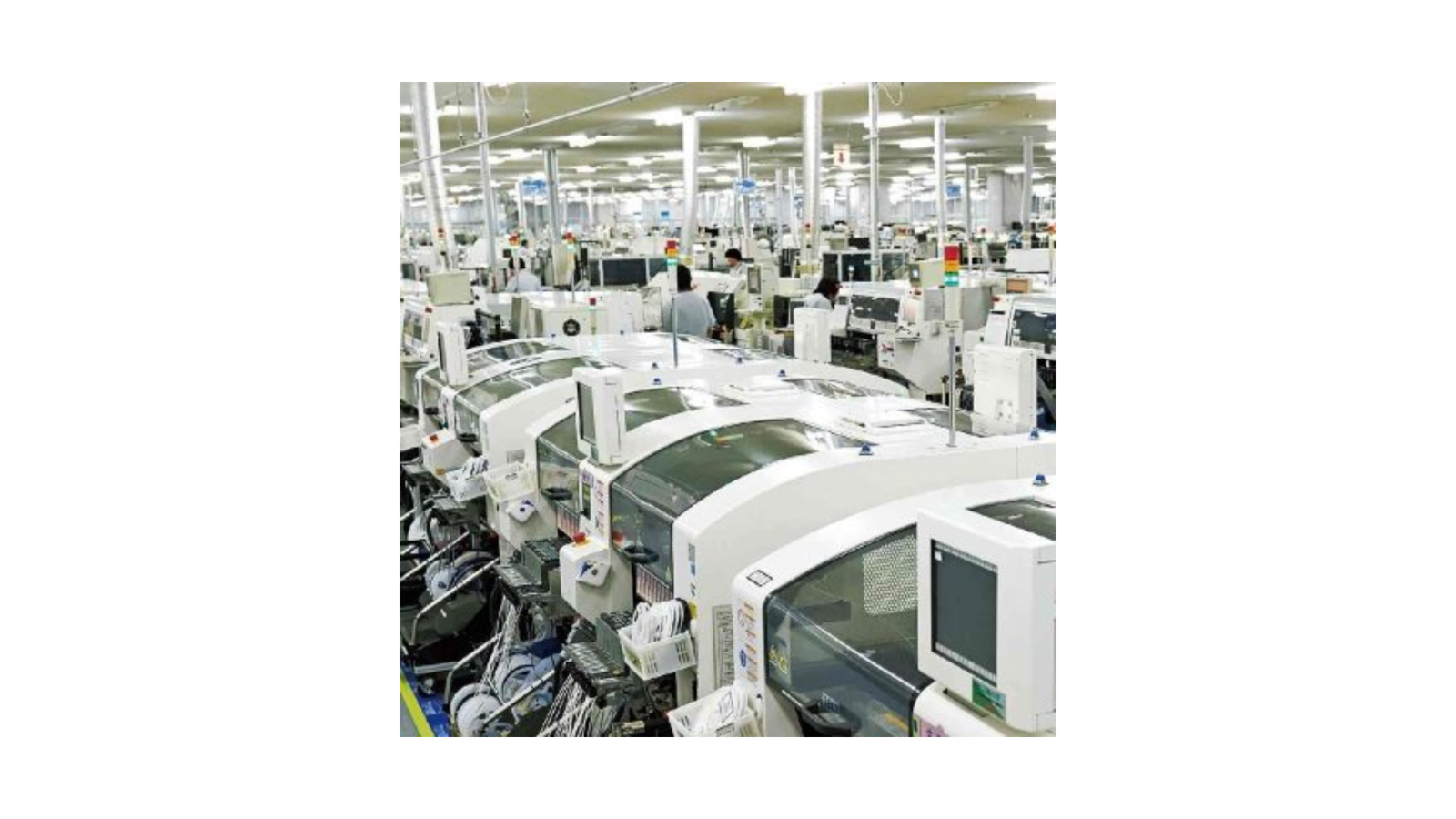

In today’s fast-moving world of electronics manufacturing, you really can’t overlook the importance of curing ovens in PCB assembly. These specialised ovens are crucial for ensuring printed circuit boards (PCBs) come out just right.

Whether it's soldering or reflow processes, curing ovens are basically the backbone of most modern gadgets.

At HJE Tech India Private Limited, we’re proud to be at the forefront of this technology, specialising in the design and sale of industrial curing ovens and equipment for the electronic manufacturing industry.

Delve into this blog to understand the importance of the curing oven in PCB assembly and how you can step up your game to meet the growing demands of the electronics market. So, let’s start!

The Role of a Curing Oven in PCB Assembly

A curing oven's primary role in PCB assembly is to apply controlled heat to set and harden materials like solder paste, adhesives, and coatings, ensuring strong, reliable connections and a durable finished product.

Key roles of curing ovens:

Curing solder paste and adhesives

Removing moisture

Binding layers in multilayer PCBs

Providing precise control

Supporting different production needs

The better the curing oven, the more reliable your finished PCB will be.

Benefits of Proper Curing for Electronic Products

A well-cured PCB ensures:

Longer product lifespan

Better thermal stability

Higher mechanical strength

Improved environmental resistance

Stronger bonding and adhesion

Better electrical insulation

In short, curing protects your investment, both in manufacturing and long-term performance.

What Happens When PCBs Are Not Properly Cured?

When PCB materials or coatings are not properly cured, they compromise the materials' intended physical and electrical properties, leading to numerous reliability and performance issues.

This highlights the importance of curing oven in PCB assembly. Poor curing can lead to:

Premature delamination

Weak solder mask adhesion

Cracking under thermal stress

Reduced dielectric strength

Moisture penetration and corrosion

Component drift due to unstable bonding

Types of Curing Ovens Used in PCB Production

While the principle remains the same, manufacturers use different curing ovens depending on the PCB material and production volume.

IC Curing Ovens: These are specialised industrial ovens that use controlled heat to accelerate chemical reactions, primarily to harden materials and ensure durable and reliable electronic components.

IR Curing Ovens: Efficient for uniform, rapid heating without direct contact.

UV Curing Ovens: Used for UV-sensitive solder masks and coatings. They cure within seconds, making them popular in fast-paced SMT environments.

UV (LED) Curing Ovens: They use ultraviolet light to initiate a rapid photochemical reaction, transforming liquid coatings, inks, or adhesives into a solid cured state almost instantly.

Choosing the right oven isn’t just an equipment decision. It's a reliability decision.

Why Choose HJE Tech India Private Limited

Choosing the right technology partner can make or break your project. At HJE Tech India Private Limited, we blend technical expertise with a problem-solving mindset that puts your business first.

Here’s what sets HJE Tech apart:

Expert-Led Execution: Our engineers, designers, and digital specialists are passionate about creating systems that perform flawlessly in real-world conditions.

End-to-End Support: From consultation and planning through development, testing, and optimisation, we stay with you every step of the way.

Focus on Quality & Reliability: Precision and consistency define our work. Whether it’s PCB design, software development, or digital services, we ensure next-level reliability.

Transparent Communication: No jargon, no guesswork, just clear updates, honest guidance, and collaborative decision-making.

Future-Ready Approach: We design solutions that evolve with your business. As technology shifts, your systems stay ahead rather than fall behind.

The Bottom Line

A curing oven may not be the most glamorous piece of equipment in PCB assembly. But it is undoubtedly one of the most critical parts. When the curing process is done correctly, you are not just finishing up a board. You are safeguarding reliability, performance, and customers’ trust.

If your business needs high-quality PCB design, assembly support, or electronic consultation, HJE Tech India Private Limited is here to help with expertise in end-to-end electronic solutions. We ensure your products meet the highest performance and reliability standards.

Get in touch with us today to improve your PCB manufacturing process.

Disclaimer: This content is for informational purposes only and was written by a professional content writer. Contact us to learn more about curing ovens!

Write a comment ...