In Surface Mount Technology (SMT) manufacturing, everyone talks about pick-and-place accuracy, reflow profiles, and AOI systems. But when it comes to where most defects actually begin, the answer is the solder paste printing stage.

The impact of solder paste printing on SMT yield and quality is far deeper than it appears on the production floor. Let’s understand the impact of solder paste printing better in this blog.

In this blog, we’ll unpack the impact of solder paste printing on SMT yield and quality and how this single process step shapes the success of an SMT line.

Impact of Solder Paste Printing on SMT yield and quality: Complete Guide

Let’s examine the role of solder paste printing and its impact on SMT line yield and quality.

1. Paste Volume Consistency Drives First-Pass Yield

When solder paste volume varies from pad to pad, defects follow. Solder paste printing accounts for 50-70% of SMT assembly quality, directly impacting first-pass yield (FPY) by controlling bridging, opens, and voids.

Too little paste leads to:

Open joints

Weak mechanical bonds

Early field failures

Too much paste?

Solder bridges

Tombstoning

Shorts under fine-pitch components

Stable printing ensures uniform deposits, which dramatically improves first-pass yield, the metric every factory lives by.

2. Fine-Pitch Components Leave No Room for Error

High-precision printers with accurate alignment and controlled squeegee pressure make the difference between smooth production and constant firefighting.

Modern PCBs are packed with:

BGAs

QFNs

0201 and 01005 components

At this scale, even a tiny printing error becomes a defect. The impact of solder paste printing on SMT yield and quality becomes especially evident on high-density boards, where manual rework is nearly impossible.

How Printing Quality Influences Long-Term Reliability

Yield isn’t just about passing inspection. It’s about performance over time. Poor solder joints caused by uneven paste deposition may pass AOI but fail months later due to:

Thermal cycling

Vibration stress

Oxidation

Consistent solder paste printing creates:

Strong, uniform fillets

Reliable electrical connections

Better thermal conductivity

In other words, quality printing protects your brand long after the PCB leaves the factory.

Why Leading Manufacturers Focus on Printing First

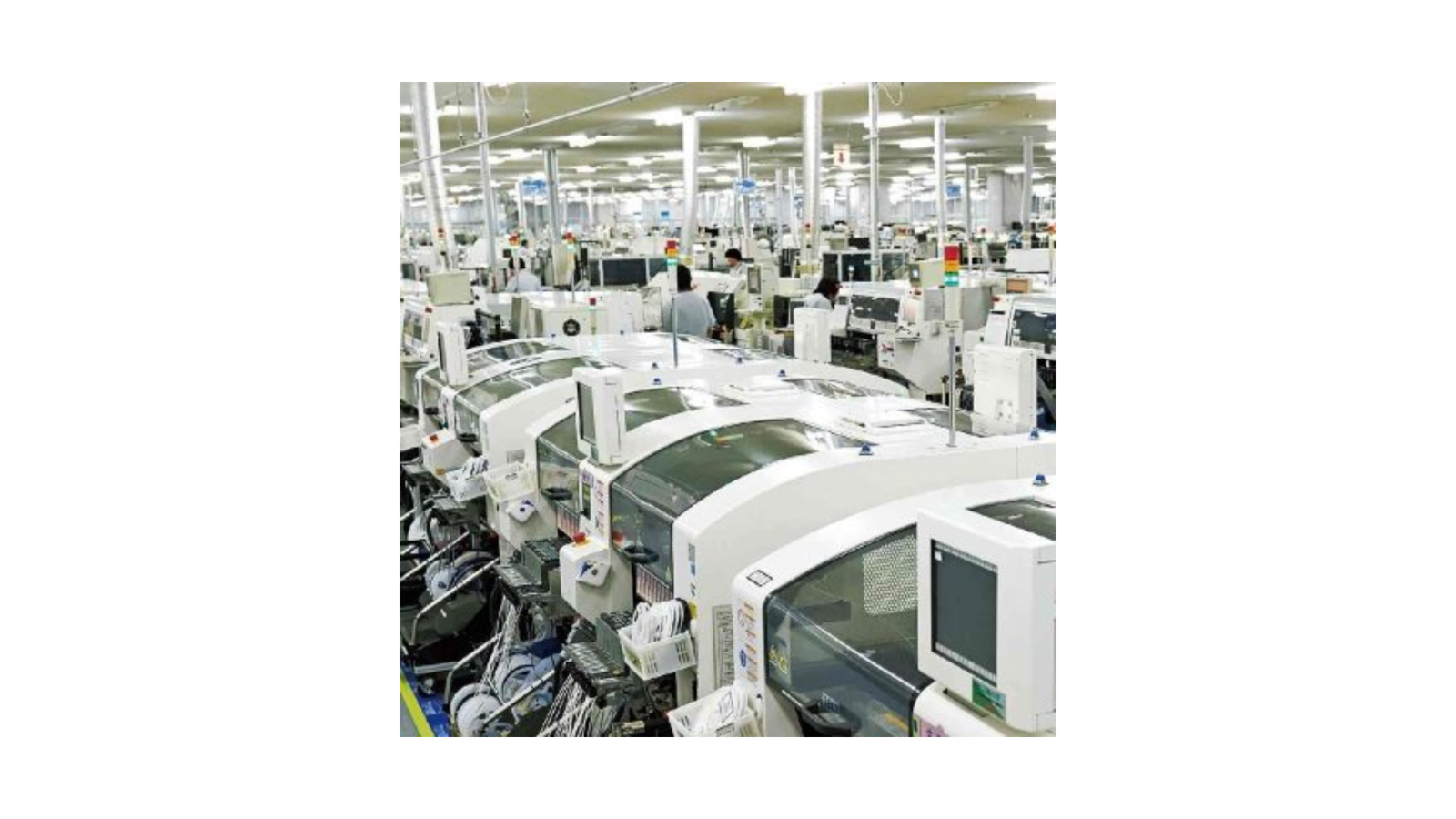

Experienced founders and plant heads focus on printing first because it is the most critical, high-impact stage of the Surface Mount Technology (SMT) assembly process.

That predictability means:

Lower scrap rates

Fewer line stoppages

Reduced rework costs

Happier customers

Practical Tips to Improve Printing Yield and Quality

Here are proven insights SMT veterans swear by:

Use the right stencil design: Aperture size, shape, and thickness must match component density.

Control squeegee pressure and speed: Too aggressive causes smearing; too light leads to poor transfer.

Maintain paste condition: Temperature, humidity, and working time matter more than most people admit.

Automate inspection early: SPI (Solder Paste Inspection) catches problems before they multiply.

Invest in stable printers: Machine rigidity and repeatability directly affect consistency.

Each of these steps reinforces the impact of solder paste printing on SMT yield and quality, turning printing from a risk into a competitive advantage.

The Bottom Line

Solder paste printing isn’t just another SMT step. It’s the backbone of yield, quality, and long-term reliability. From fine-pitch components to high-volume production, its influence is impossible to ignore.

Manufacturers who understand the impact of solder paste printing on SMT yield and quality don’t chase defects downstream. They prevent them at the source.

If you’re looking to strengthen your SMT process, HJE Tech India Pvt. Ltd. offers advanced SMT equipment solutions, solder paste printers, inspection systems, and expert support to help you achieve consistent yields and superior quality.

Get in touch with HJE Tech India Pvt. Ltd. to upgrade your SMT line and build quality into every board, right from the first print.

Disclaimer: This content is for informational purposes only and is written by a professional content writer. Contact us to learn more about the solder paste printing machine!

Write a comment ...