For those new to electronics manufacturing, we bring you this conformal coating guide so that you can better navigate the world of PBC manufacturing.

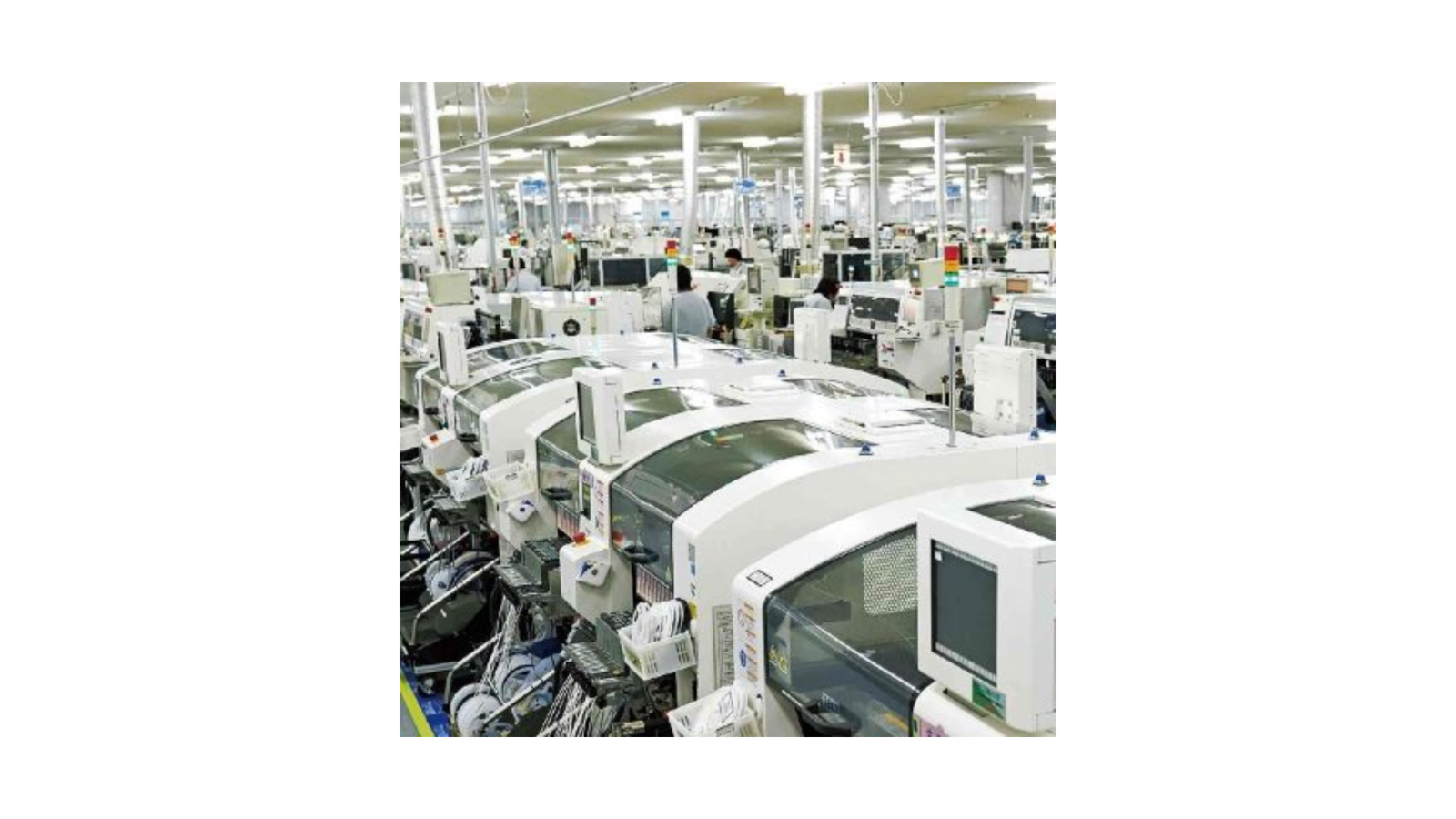

Let’s understand the working of an effective SMT line!

From consumer electronics to aerospace systems, conformal coating ensures long-lasting functionality even in extreme conditions. Understanding their nuances helps manufacturers make better decisions for efficiency and quality of their products.

This conformal coating guide introduces beginners to the essentials of how this process enhances the reliability and performance of printed circuit boards (PCBs).

Keep reading to know more!

Conformal Coating Guide: Knowing the A to Z of SMT Machines

What Is Conformal Coating?

Conformal coating is a thin protective layer applied to printed circuit boards (PCBs) and electronic components. As the name suggests, the coating “conforms” to the shape of the board and its parts, creating a barrier against environmental damage.

Unlike bulky enclosures, conformal coatings are almost invisible and lightweight, adding very little thickness to the board. This makes them perfect for electronics that need both durability and compact design.

Why Does SMT Line Need Conformal Coating?

Electronics are vulnerable to a wide range of environmental factors such as moisture, dust, chemicals, and temperature changes. Without protection, these elements can corrode circuits, cause short circuits, or even lead to complete device failure.

Conformal coating acts like a shield, helping the PCB resist these threats while still allowing heat to dissipate and the board to function normally.

What are the Types of Conformal Coating

Several materials are used for conformal coatings, each with its own unique strengths.

1. Acrylic coatings are popular for their ease of application and removal.

2. Silicone coatings are chosen when resistance to extreme temperatures is required.

3. Urethane coatings provide strong chemical resistance.

4. Epoxy coatings are known for their durability in harsh environments.

Manufacturers choose the type of coating based on the specific conditions the product will face.

How to Apply Conformal Coating on the PCBs?

The coating can be applied in different ways depending on the production scale and the level of protection required. Some boards are dipped into the coating solution, while others are sprayed or brushed.

For high-precision work, selective coating machines apply the material only where it’s needed, avoiding connectors or areas that shouldn’t be covered. After application, the coating is cured using heat, UV light, or moisture, depending on the type of material used.

What is the Advantage of Conformal Coating

The biggest benefit is protection. Conformal coating extends the lifespan of electronic devices by preventing corrosion, electrical leakage, and damage caused by moisture or contaminants.

It also helps boards withstand vibration and thermal stress, which is critical in industries like automotive, aerospace, and industrial equipment.

For consumer electronics, it ensures devices remain reliable even with daily wear and tear.

What are Some Common Applications of Conformal Coating Machines?

Conformal coatings are widely used in industries where electronics face challenging environments. They are essential in automotive systems exposed to heat and vibration, in aerospace equipment where reliability is non-negotiable, and in medical devices that must remain functional under strict conditions.

Even everyday products, such as smartphones and household appliances, often rely on conformal coatings to enhance durability.

Final Thoughts

With the increasing complexity of SMT machines and high-density circuit boards, maintaining performance and longevity through precise coating processes has never been more important.

The right conformal coating machines achieve consistency, efficiency, and high-quality protection at scale, minimising the risk of failure in critical applications.

Expert Conformal Coating Solutions Await You

HJE Tech India PVT. LTD. offers advanced conformal coating machines that ensure every circuit board gets the right level of protection without compromising performance.

Whether you’re building consumer gadgets, industrial machines, or mission-critical electronics, we deliver reliable, high-quality conformal coating solutions that keep your products safe and long-lasting.

Disclaimer: The information provided in this content is just for educational purposes and is written by a professional writer. Consult us to know more about SMT machines.

Write a comment ...